Agricultural buildings, sheds, and barns

Healthy climate, efficient construction, and sustainable structures

Building with structural timber offers significant advantages in the construction of agricultural buildings and barns—a better microclimate, humane treatment of animals, economic efficiency, and sustainability.

Thanks to its natural properties, wood provides a healthy environment in the barn and allows for quick and efficient construction.

Key advantages of wooden structures

Optimal climate control

Wood has high thermal capacity and regulates humidity. It insulates from the cold in winter and protects against overheating in summer, reducing stress for animals.

Better animal welfare

Natural surfaces and pleasant acoustics create a calm environment. Wood also has antibacterial properties that can inhibit the growth of bacteria.

Low weight and high load-bearing capacity

Compared to steel or concrete, wood is significantly lighter but offers comparable stability. This reduces foundation costs and allows large spans to be bridged for spacious, column-free halls.

Slim and efficient structures (LVL)

By using LVL, the cross-sections of columns and beams can be reduced. This provides more usable space and improves the architectural appearance of the building.

Fast and clean installation

The high degree of pre-preparation and factory production significantly reduces on-site construction time.

Sustainability and excellent environmental footprint

Wooden buildings act as long-term CO₂ storage and can be recycled at the end of their service life. Wood is a renewable resource that stores CO₂ during its growth. Every cubic meter of wood used in construction removes approximately one ton of CO₂ from the atmosphere.

Fire protection

Contrary to common misconceptions, wood offers a high level of fire safety. While unprotected steel quickly loses its load-bearing capacity due to heat, wood retains its stability longer thanks to its protective char layer.

Wooden structures often achieve a fire protection class of F30 without additional measures, while steel structures often only achieve F0.

Chemical resistance

Unlike steel, wood is resistant to many chemical influences. This makes it particularly suitable for agricultural and industrial buildings with aggressive environments.

Cost-effectiveness

The combination of glulam (BSH/GLT) and LVL allows for optimization of the amount of material used. The lower weight compared to concrete solutions reduces installation costs and foundation requirements.

Materials used (BSH and LVL)

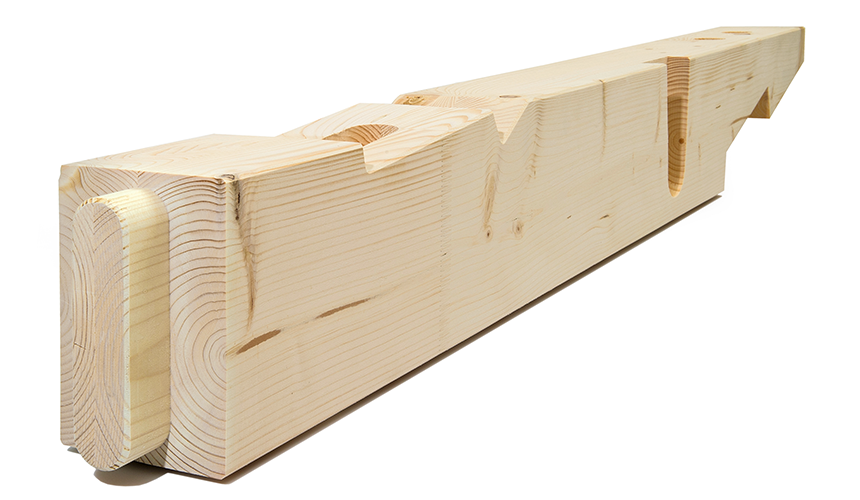

Laminated wood (Glulam / BSH / GLT)

Consists of at least three dried lamellas of coniferous wood glued together with parallel fibers. This is the classic material for long-span beams and complex shapes in engineered wood construction.

Laminated veneer lumber (LVL)

A highly efficient material made from approximately 3 mm thin glued veneer layers. LVL has a significantly higher strength than laminated wood and allows for thinner cross-sections under the same load.

Long spans without intermediate columns

The high load-bearing capacity of both materials allows spans of up to 60 m and more, which is ideal for hangars, barns, and warehouse buildings.

Design

Whether you need consultation or comprehensive design services, TimberTech is at your disposal. You can also take advantage of individual services.

Right from the initial design stage, we ensure that the construction will be executed with precision. We do not limit ourselves to standard solutions – we analyse your requirements and apply our expertise and that of our partners to achieve the optimal solution for the project.

We place particular emphasis on work efficiency, cost-effectiveness, and humane treatment of animals.

We use specialised CAD design software to create optimal designs for each specific project. Optimally coordinated and pre-planned work processes contribute significantly to improving the entire construction process.

Types of structural solutions

Structures with internal columns

A structure with 1 to 4 rows of internal columns is a classic and cost-effective option. Internal columns facilitate the installation of equipment in the barn. For wider spans, the columns can be combined with steel tension rods to minimise the number of columns required. The columns can be made of either wood or steel.

Structures without internal columns

For roof pitches of 18° and above, a structure without internal columns with steel tension rods is often the most economical option. Steeper roof pitches are also possible.

This option offers flexibility for future conversion, facilitates the installation of lighting, and allows for a variety of modifications to the building. It also ensures maximum freedom in the arrangement of equipment in the barn.

Main Details and Solutions

Roof

Possible solutions:

- sandwich panels

- sheet metal

- roof tiles

- green roof

External Walls and Facades

Wood Cladding / OSB

Wood is a renewable resource and supports the sustainability of the project. It has natural insulating properties and regulates humidity inside the barn.

Sheet Metal / Sandwich Panels

Steel trapezoidal sheets or sandwich panels, resistant to environmental influences and requiring low maintenance. Available in various RAL colors.

Side Ventilation (Lift-Up Wall)

Side ventilation, functioning as a lift-up window, is controlled via a central drive system. The elements are adapted to the spacing between the columns, allowing adjustment up to the roof and ensuring optimal ventilation.

Available in heights of 100 cm, 120 cm, 150 cm, and 200 cm. The areas above the side ventilation do not require cladding. The drive system can be manual or electric with a control system.

Ridge Ventilation and Natural Lighting

The option for natural lighting and ventilation along the ridge ensures an optimal climate inside the barn and creates the best living conditions for the animals.

Multiwall polycarbonate panels made of hail-resistant acrylic polycarbonate do not yellow. They provide excellent thermal insulation and transparency close to that of glass.

Concrete Works and Foundation

Before construction activities begin, a preliminary meeting is held on site. All details to be included in the construction project are clarified jointly. Execution is carried out by our specialists or subcontractors.

A Sustainable Solution for Modern Agricultural Construction

Agricultural buildings with load-bearing structures made of glulam (BSH/GLT) and/or LVL are a highly efficient and sustainable alternative to steel and concrete structures. They provide an optimal climate for the animals, cost efficiency, and long-term reliability.